WEB-BASED ASSET MANAGEMENT SYSTEM

FOR MOBILE ASSET DEPLOYMENT MANAGEMENT

The asset management solution for movable assets and mobile assets is different in many respects to the traditional enterprise assets and/or inventory management solution. AVANTE International Technology, Inc. combines its expertise in asset and personnel tracking and web-based asset tracking and visibility solution technologies to provide a comprehensive and web based management tool to optimize usage of mobile assets along side with more traditional assets. The technologies utilized includes barcode, RFID, GPS, WiFi and Bluetooth local area networking and communications, GPRS-Broadband and Satellite wide area networking and communications.

There are substantial inefficiencies in traditional enterprise asset management systems and solutions for managing movable or mobile assets. Examples of mobile assets include configured election and voting systems, construction assets and systems, utility assets and systems, oil and gas rigs and systems, etc. In specialized operational environments, mobile assets and configured systems are deployed repeatedly to different physical job sites and utilized by different sets of personnel. In many circumstances, supplies and parts are consumed and/or destroyed that must be replenished before a new deployment. Also, equipment, supplies and tools that comprise the system need to be tested independently as well as in tandem with other equipment to ensure proper system functioning for more complex operations.

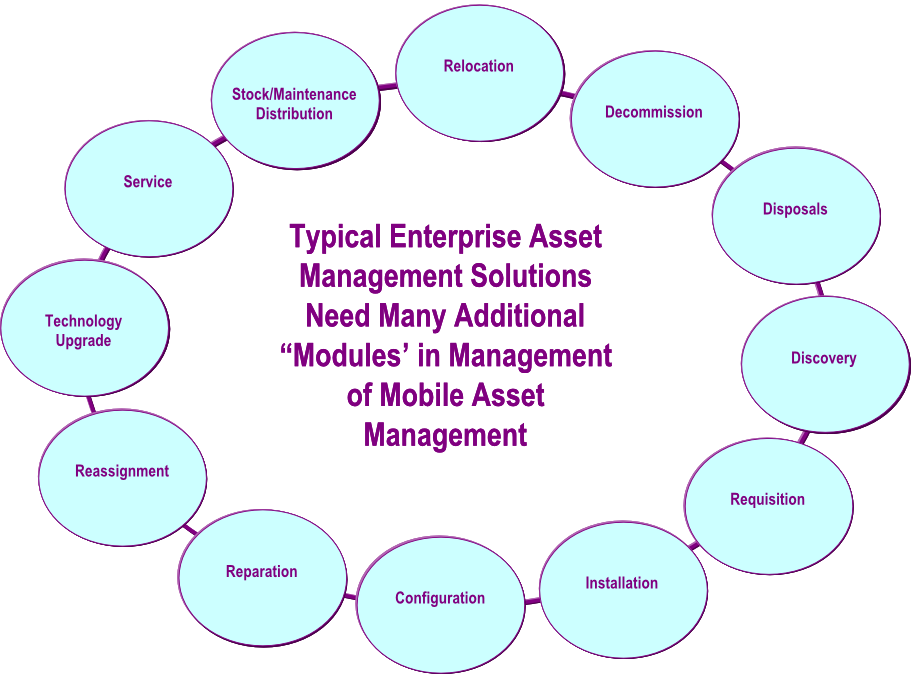

The following representation of typical asset management modules and functionalities clearly miss many different aspects in managing mobile assets and configured systems:

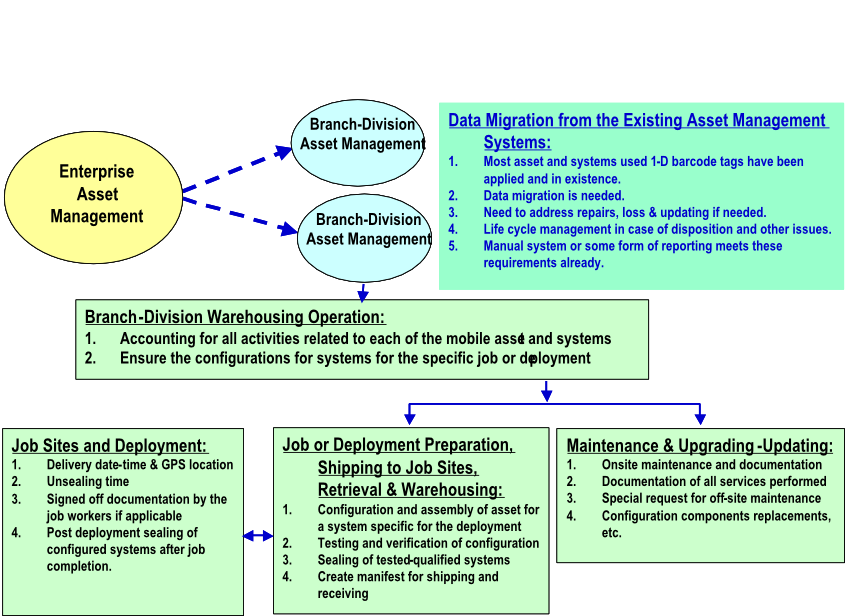

One of the best examples of mobile and movable asset management requirements is seen in the deployment of rigs in the oil and gas industry. Drilling and exploration companies have numerous assets distributed to several locations and following each asset is critical/ for oil and gas face unique challenges in order to manage their assets. One challenge is that the assets are moved between deployments to different physical locations, some of which may be off or onshore. Similar to many movable and deployable assets in utility companies, the deployed assets of drilling and exploration companies are moved from job sites to division or branch warehouse, rigs, repair facilities and maintenance facilities. Assets may even move from one country to another. Another challenge is that not only do the assets themselves need monitoring, but the maintenance cycle of rigs and the maintenance of supplies for repairs must be managed and tracked.

The key distinguishing function and feature of this system is to provide seamless “end-to-end” tracking of assets not only for their traditional life-cycle but also for periodic deployments as well as tracking of regular or irregular asset maintenance.

ASSET MANAGEMENT SOLUTION for mobile assets must incorporate end-to-end tracking and documenting of the processes in each deployment of mobile assets along with supplies and configured Systems:

- Automatically upload and update the individual processes

- Tracking and documenting quarterly or periodically maintenance by who-when-what-where

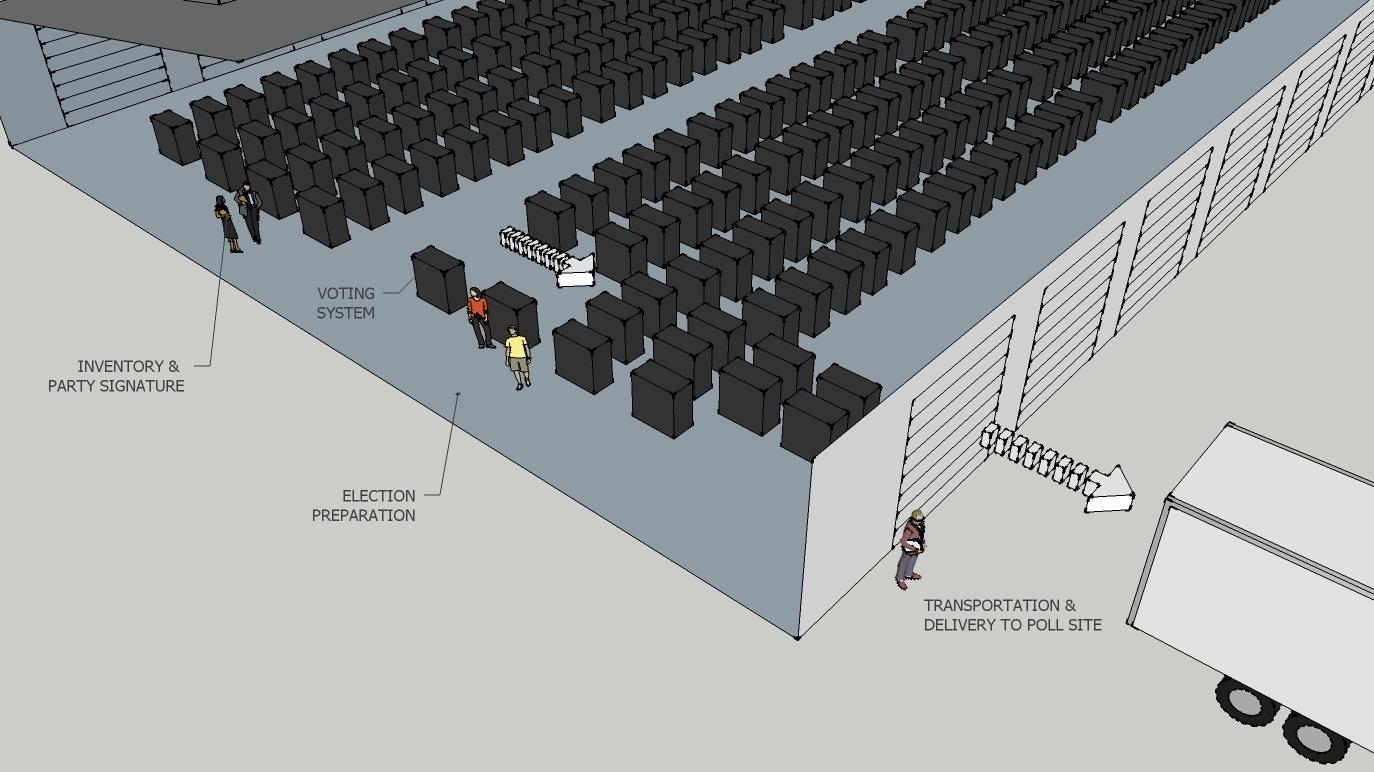

- Tracking and documenting of the “preparation for deployment” by who-when-what-where

- System configuration and loading for the scheduled deployment

- Testing and verification

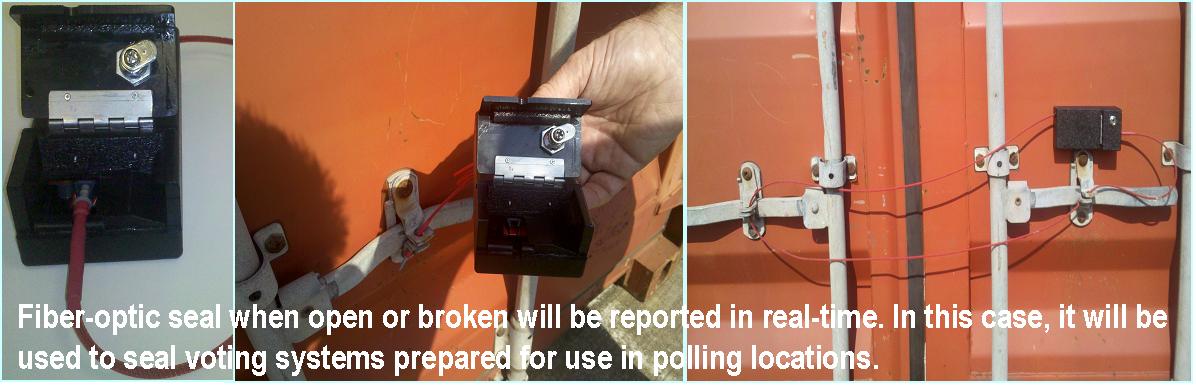

- Sealing for security

- Completeness and conformance of the preparation processes

- Tracking and documenting the delivery from warehouse to the job site

- When and what are picked up by the delivery truck

- When and what are delivered to each job site by the delivery truck

- Tracking and documenting the retrieval from job site to the warehouse

- When and what from the precinct loading onto the delivery truck

- When and what is unloaded at the warehouse from all job sites by the delivery truck

To achieve this goal of “End-to-end” tracking and documenting of the processes in each deployment or job for all of the assets, supplies and configured systems at each warehouse, a specialized data capturing and documenting device must include the following functions and features:

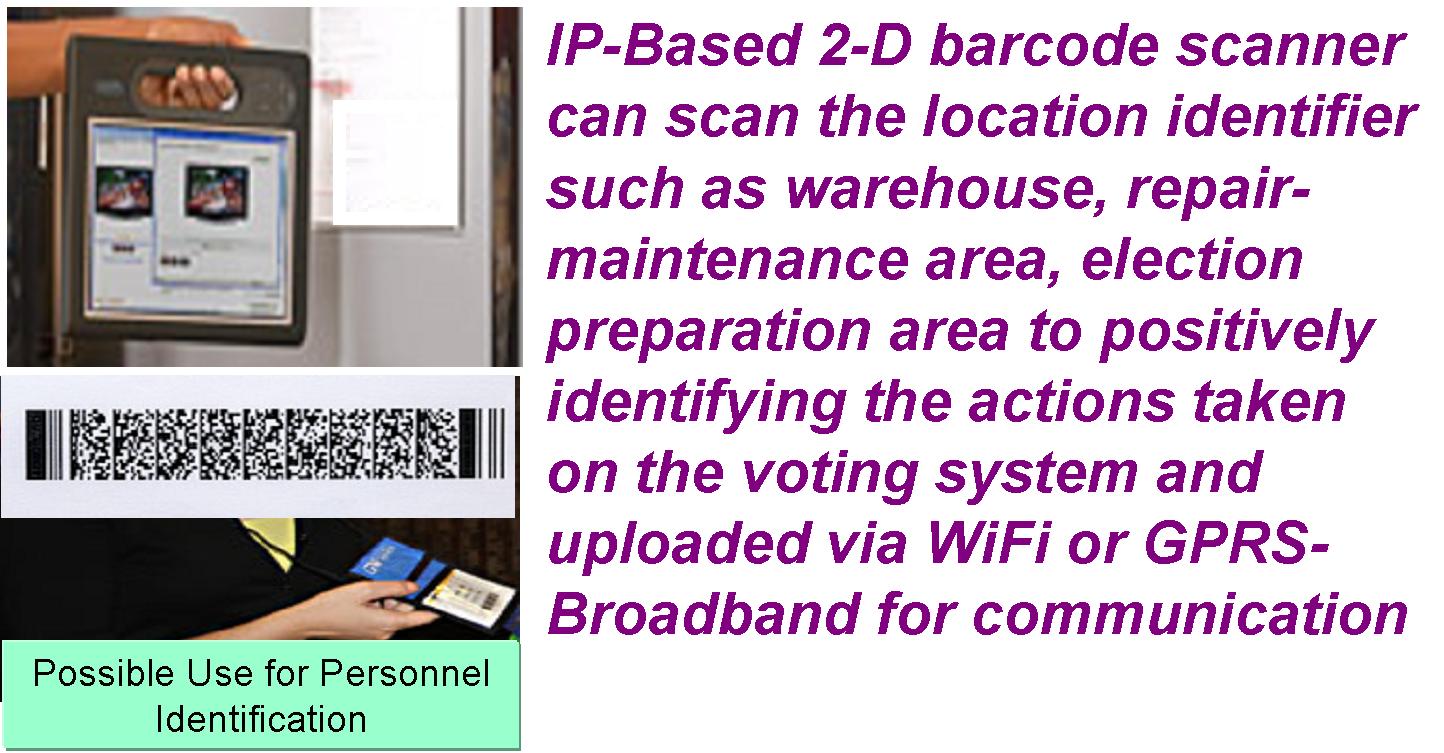

- IP-Based so that it can attribute “who” is performing the tracking and documentation

- 2-D barcode capability to have access to the key information of the cargo and ability to look up data that may only be available from the web-based database. AVANTE uses 1- and 2-D barcodes and in some cases, “QR” format to provide this feature automatically and seamlessly.

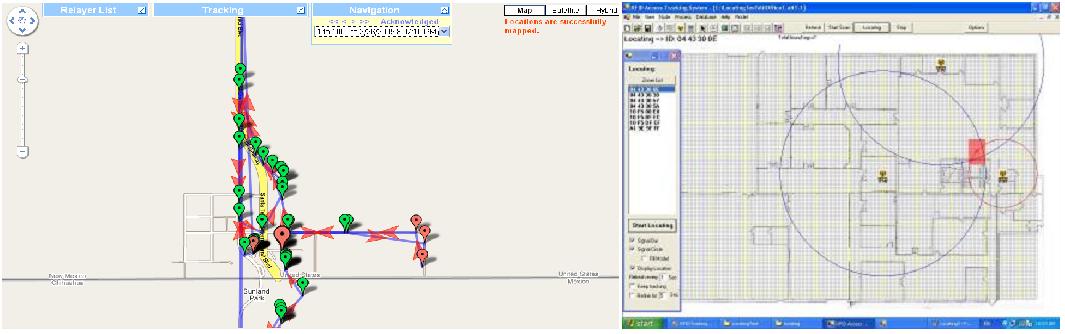

- Embedded GPS-GPRS (Broadband) capability for providing real-time updating of the locations (RTLS) when the maintenance, delivery and other movements of the asset and systems whenever they are scanned based on the required activities of:

- Warehouse and job site receipt process

- Periodic maintenance activities

- Preparing asset and configured systems for job or deployment

| IP-Based 1-and 2-D barcode scanner can scan the location identifier such as warehouse, repair-maintenance area, election preparation area to positively identifying the actions taken on the voting system and uploaded via WiFi or GPRS-Broadband for communication |

FUNCTIONS OF MOBILE BARCODE SCANNER | ||

FUNCTION | TECHNOLOGY | SOLUTION |

| Tracking Identifier | 2-D barcode in combination with 1-D barcode | Incorporating additional details besides the item identifier number such as:

|

| Location Data | Embedded High Sensitivity GPS and optional Gyroscopic Tracking | Embedded GPS provide location and date-time of when the system is being scanned for specific activities such as:

|

| Real-Time Updating of Event | Embedded GPRS and Broadband capability in addition to stationary WiFi network | Embedded Broadband and/or GPRS updating status in real-time for the specific events in the web-based database:

|

| Signature Capturing and/or biometric data Capturing | Touch-screen (using stylus) for direct signature capturing on the scanner level and fingerprint or other biometric data capturing devices | Instead of the traditional paper based on fixed station computer-based solution, this enhances:

|

| Alerts and Prompting | SMS and other communication via broadband or GPRS |

|

- Preparing mobile asset and configured systems for the specific job or deployment with system testing and verification

- Delivery asset and configured systems to job sites

- Retrieval of asset and configured systems from all job sites

| IP-Based 2-D barcode scanner with embedded GPS for location tracking and GPRS-Broadband for communication can provide real-time updating of status of asset and configured systems delivery to and from the job sites |

- Ability to capture digital signature (digitized signature on the scanner) and on the computer accessing the web database.

- Ability to directly capture biometric data and/or verification using fingerprint or facial image biometrics.

- Ability to enter manual data such as security seal numbers, etc.

For More Visibility and Automatic Data Capturing, Passive RFID Portal and/or Active RFID Monitors are useful additions:

- Providing optional passive RFID portal

- Based on UHF with reading distance of at least 10 ft in orientation to accomodate the portal design

- Portal reader for critical entry-exit of the county warehouse for the asset and configured systems

- To provide possibility to automatically document the completeness of the asset and configured system to be delivered

- Providing optional passive RFID portal

- Providing optional active RFID monitoring portal

- Based on 443 MHz active system with sensor-tag for motion and optical fiber seal to allow the direct and automatic monitoring of access to each asset and configured system

- Monitoring reader for the local warehouse for the asset and configured system

- To provide the possibility to automatically document access to each asset and system and removal from the warehouse to job sites or other purposes

FUNCTIONS OF OPTIONAL UHF RFID PORTALS FOR NODAL VISIBILITY | ||

FUNCTION | TECHNOLOGY | SOLUTION |

| Tracking Identifier | UHF Passive RFID with unique identifier and up to 2K bytes of data | While RFID can have extensive data, it is best used to automatic check and document events using the same item identifier number as barcode.

|

| Location Data | Fixed portal typically located at the door or gate entrance/exit for nodal visibility | Nodal based location to provide primarily date-time of when the system is being removed or returned for specific activities such as:

|

| Real-Time Updating of Event | Portal read data transmitted using Ethernet via stationary WiFi network | Portal records an event and update with status in real-time in the web-based database:

|

| Automatic Document and Verifying the Configuration of a system | Reading multiple tags at the same time |

|

| Instant Alerts and Prompting | The portal can provide alerts on systems that are wrongfully being taken out of the warehouse |

|

FUNCTIONS OF OPTIONAL ACTIVE RFID RTLS FOR END-TO-END VISIBILITY | ||

FUNCTION | TECHNOLOGY | SOLUTION |

| Tracking Identifier | Active ZONER RFID tag with unique identifier and up to 2K bytes or more for data | While active RFID can have extensive data, it is best used for more secure end-to-end tracking of intrusion and movement for critical systems.

|

| Location Data | Fixed using the received signal strength to provide real-time location of the tagged systems | RTLS to provide location and movement in real-time including when, where, what and who are involved in:

|

| Real-Time Updating of Event | The RTLS networking of monitoring reader transmitting data via stationary WiFi network or embedded GPRS | RTLS Monitoring network records an event and update with status in real-time in the web-based database:

|

| Automatic Document and Verifying the Configuration of a system | Reading multiple tags at the same time |

|

| Instant Alerts and Prompting | The RTLS monitoring units can provide alerts on systems that are wrongfully being taken out of the warehouse |

|

Web-Based Database and Role-Based Access to the Information in Providing Real-Time Visibility of Asset and Configured Systems for Possible Asset Utilization:

- Hosting services with redundancy

- Role based access

- Real-time updating of status of individual asset and configured system

- Facilitate efficient job and system deployment and accountability